Who is Mishimoto?

When it comes to saying the name Mishimoto, the automotive enthusiast's mind goes to something that is foreign or a brand that is not stateside. In reality Mishimoto was founded in 2005 with their headquarters being located in New Castle, Delaware where their goal is to create superior aftermarket cooling system upgrades for a variety of vehicles.

The Mishimoto state of the art engineering facility rests on 27,000 sq ft of work space allowing their team to design, create, and test the products that are set to enhance the driving experience for any automotive enthusiast. Their products are geared toward fitment, quality, and appearance, they do not seek to only produce a product for the sake of producing a product, they want the product to outperform the OEM specifications and push the limits.

So, what would make you want to purchase a Mishimoto product? Mishimoto’s product line covers a wide variety of products that will enhance the cooling, feeding, or extracting of the various outputs that the engine puts out. Their product line covers items from intercoolers to oil coolers, intake systems to catch cans, and charge pipes to exhaust systems. Now it’s just a matter of finding the perfect item, which fits your model, that has the same goal in mind of what you are looking to optimize the performance out of.

Exhaust Systems:

Not only capable of creating a different sound, an exhaust system can be stylish and Mishimoto has proved that with their systems. Being constructed out of 304 stainless steel they are able to improve the performance output over the factory system by eliminating the large bulky factory muffler for some well designed high flow Helmholtz resonators in their Pro systems and mufflerless piping on their Race systems.

The Helmholtz bullet style resonators are integrated into the system to allow the extra volume but also minimize the loud highway drone. Mishimoto has gotten a bit creative when it comes to their exhaust design as well, it's not only the tips they put attention to in their details. Their Pro V8 systems have the Helmholtz resonators but also integrate a J-Pipe allowing for the extra exhaust volume to be directed helping with the drone noise at highway speeds. Either system that is chosen, be it Pro or Race, is going to be constructed out of the same 304 stainless steel and tig welded to showcase the excellent quality behind the brand.

Their various combinations of exhaust systems all integrate to the specific models flawlessly and sound excellent once put to the test, but at the end of the day, the tips are one of the most important views of any exhaust system. Each Mishimoto system has been engineered to reflect the highest quality from the start of their system, all the way down to the tips. With tip finish options being offered in both a High Polished and a Black Finish, making the right choice for your build will come down to your style and final desired appearance. Either choice of tips, Mishimoto has put their stamp of excellence on the outer bank of the tip with their prized brand logo. The signature “M” is etched on the outer tips in a tasteful finish keeping the eye concentration on the large tip(s) itself.

Intake Systems:

On the top of the list of first mods is a cold air intake, since Mishimoto prides themselves in improving air flow, this mod is on their list of firsts to tackle as well. Your engine is like an air pump, the better the flow the more efficient it can work, a high flowing intake allows the engine to breath better which in turn optimizes the performance out of the engine.

Mishimoto’s approach to improving on a factory intake starts with dissecting the factory components to see where things can become more efficient. They measure the MAF sensor housing diameter to ensure they are able to follow similar factory specs to prevent a check engine light from occurring. Then they move into improving the intake elbow, typically the factory component is constructed of silicone with various diversions that create turbulence with the air flow. Mishimoto is able to smooth out the intake elbow by creating their own elbow for a smooth air flow operation. Finally the all important air box, this is the centerpiece of any intake system since it will display the all important filter and improve the aesthetics of the engine bay.

Using 3D printed prototype parts, Mishimoto is able to design the MAF sensor housing quickly when compared to other methods. Their engineers are able to quickly draft the housing for testing and make any adjustments as necessary when they measure the dynamics of their design. When Mishimoto finds that the newly designed MAF housing is performing, without causing any check engine light issues, they are able to finalize the design and produce a near final version of the product.

Mishimoto takes a similar approach to the intake tube, using 3D printed prototype parts they are able to measure air flow characteristics prior to making a final production piece out of silicone. The goal is to get as much air as possible to the throttle body so that it follows with the air-stream into the engine as smoothly as possible. After some iterations of the intake tube and when they see improvements in air flow, they are able to finalize their silicone tube design making sure all the necessary factory connection points are met.

Now on to making the intake look good under the hood. Using a steel box, Mishimoto forms the lower portion of their shield, ensuring to keep all the tabs necessary to mount right back in the factory location. They integrate their MAF housing design so it works seamlessly with the shield and keeps any unwanted engine bay heat out of the box. Finally they top the shield off with a steel top that houses the all important filter. The entire box is finished in a powder-coated Black finish to keep as much of a factory feel as possible but still keeping an aftermarket look to the final product.

Catch Cans:

Along with keeping the engine happy on the intake and exhaust side, Mishimoto also dabbles in some internal engine care in the form of a catch can system. A catch can help capture oil deposits that are sent through the PCV system. These oil deposits are a combination of fuel and oil vapor that travels through the vacuum system and are cycled back into the intake manifold, then returning back into the combustion chamber.

The combination can cause what is known as carbon build up, a catch can is able to assist in minimizing the amount of oil deposits that are sent through the system. Mishimoto’s engineering team has been able to source the main PCV line that allows more oil deposits to travel through the system. With extensive testing they are then able to determine the layout of the catch can components to properly extract the fuel and oil vapors traveling through the system.

Mishimoto integrates a baffling system to their catch cans that is able maximize air-oil separation keeping as much of the oil deposits retained in the catch can. Some kits may vary in size of catch can, this can be limited by engine bay space or necessary functions, but all of them are built using a similar baffling system that consists of an air diverter, baffle, and a bronze filter.

The air diverter is the first piece of the can that the incoming air hits, it also directs the flow of the incoming air to optimize the effectiveness of the can. This is accomplished by directing the vapor to the baffle and bronze filter.

The baffle has a dual function, initially it serves as a cover to keep as much of the oil from moving around during high acceleration times. Secondly the baffle assists in additional internal surface area for the fluid to condense.

The bronze filter is a final source for separating the oil vapor from the air going through the catch can. The 50 micron filter will catch any of the smaller particles from reentering the PCV system.

Intercoolers:

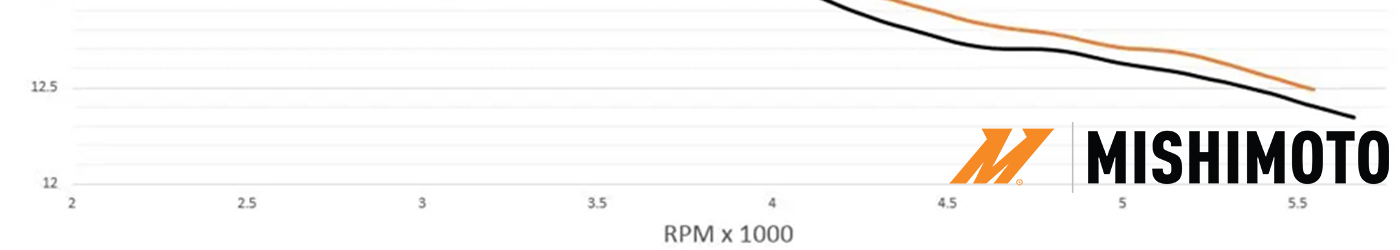

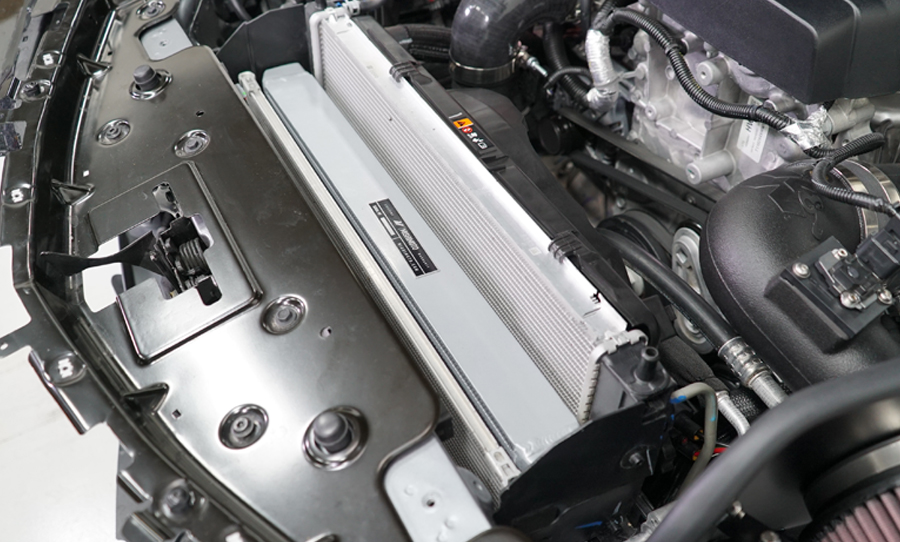

Intercoolers are more commonly air to air and are cooled by the fresh air from the front end of the vehicle, there are some cases where an additional air duct may be used to direct air to the intercooler. An intercooler is typically applied to boosted applications, similar to those found in the 2.0L Camaro. There is a Hot and Cold side to each intercooler, the Hot side refers to air that is provided from the turbocharger and the Cold side refers to air that is on the other end of the intercooler, this air has been cooled and is being fed back into the charge system.

Air to air style intercoolers are very efficient but the down side to them is that they will require forward motion to optimize the cooling effect. At idle or with a stationary vehicle, these coolers can heat soak, which will increase intake air temperatures. Once the vehicle is in motion the cooling effect will continue to take place.

Oil Coolers:

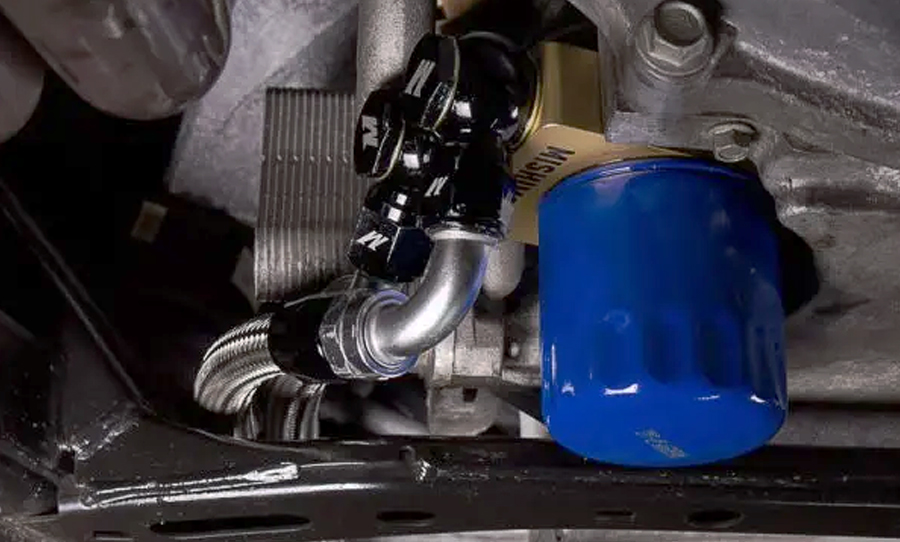

Oil coolers are typically necessary to keep a consistent optimal temperature for the oil supply. Be it engine or transmission oil, the coolers are typically an external block that is remote mounted to allow airflow to cool the tube in the cooler which provides the lower oil temperatures. As the liquid is pumped through the tubes and channels, the external fins allow for the heat dissipation or heat transfer, keeping the oil temperatures optimized for performance.

For applications specific to the Camaro, Silverado and Sierra, these coolers can be found for either the engine or transmission. With the versatile designs and engineering behind Mishimoto, they created a way to optimize the cooling effects to keep the average temperature down over the factory units.

Radiators:

A radiator, like any other style cooler, is designed to keep the engine temperatures from boiling over causing catastrophic issues. Mishimoto knows cooling is an important factor with the heart and soul of your vehicle, so their radiators are designed to be capable of lasting a lifetime while keeping underhood temperatures at bay.

Being constructed completely out of Aluminum their radiators are designed to allow more flow with their larger end tanks and larger core. The larger production attributes allow for more coolant to be placed in the system keeping the engine happy with fresh cycled coolant. Using an internal core of a strutted tube, Mishimoto has been able to reinforce their core design that not only allows for more effective cooling but strengthens the radiator as a whole.

In closing, Mishimoto is a US based company that seeks to improve your vehicle in various sections of any platform. From exhaust systems to catch cans to radiators, there is no place that Mishimto won't look to see if they can't find an area to improve over the factory components. The quality driven brand is out to provide products that will allow you to enjoy the drive and keep you behind the wheel of your ride. Now get out there and push the limits with Mishimoto!

FEATURED MISHIMOTO PRODUCTS

Recent Posts

-

-

Tariff Alert: Beat the Price Hike on Wheels & Body Components

We wanted to share some important insights regarding tariffs and the growing impact they may have …Apr 10th 2025 -

Camaro Models by Year: An In-Depth Look at Chevrolet's Iconic Muscle Car

Welcome to our journey through the storied past of the Chevrolet Camaro, a quintessentia …Dec 15th 2023